Processes and Technologies

- Advanced patented wireless technology

- Full electronic design and firmware development.

- High quality, cost effective electronics contract manufacturing (CM).

- High quality complex plastic moulding injection (double-shot mould).

- Membrane switch overlay design and manufacturing.

- Metal stampings and logo/ name plates.

- Transformer design and manufacturing.

- Full box build and turn key integrations, including testing and packaging.

Wireless Automation Technology

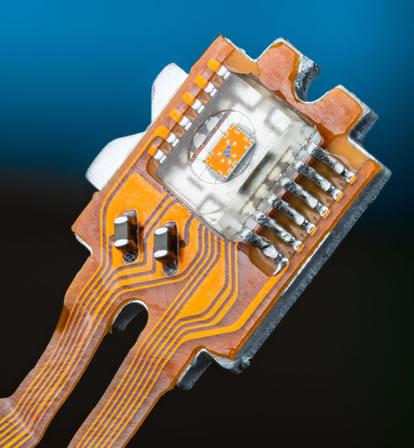

The Quest radio module is customized for each application. Customization parameters include data rates, transmit power, dynamic transmit power control, topology (point-to-point, star, dynamic mesh), antenna configuration and data interface. The module can also be modified to fit into the form factor of your product. We’ve done the hard part of designing the module, the easy part is making it work for you.

MANUFACTURING SOLUTIONS

WIRELESS TECHNOLOGY

The Quest WETH® Radio Module Can Be Customized For Any Application.

Patents issued by the U.S. Patent Office for Quest’s novel and cutting-edge technology providing robust wireless communications solutions.

Engineering, quality and manufacturing expertise set us apart from other custom cable manufacturers.

PRECISION METAL STAMPING AND TOOLING

Operating more than 20 punch presses—ranging in size from 20 to 120 tons—we can produce simple to more complex shapes and custom metal stamping from dies designed in our own tool and die department. In addition we have a full anodize, chemical etch and printing departments to add the various finishes and printings our customers require and expect from professional metal stamping services.

METAL FABRICATION

Quest Technical Sales and Marketing specializes in custom precision sheet metal fabrication using state of the art technology that includes; automated metal CNC punching, laser and water jet cutting, stamping, forming, bending, welding, and machining. We also have both wet and dry finishing/painting and silk screening capabilities in-house.

NAME PLATES AND LOGOS

We can work with both plastic and metal materials such as PC, PET, Acrylic or Aluminum, Steel, Stainless Steel, SUS, Copper and more. Based on the design, we apply Printing, Epoxy (PU Doming), Diamond cut, Anodizing, Sand Blasting, Hairline, and other surface treatments on the nameplate and logo’s. In addition, all parts are produced in a class 1000 clean room.

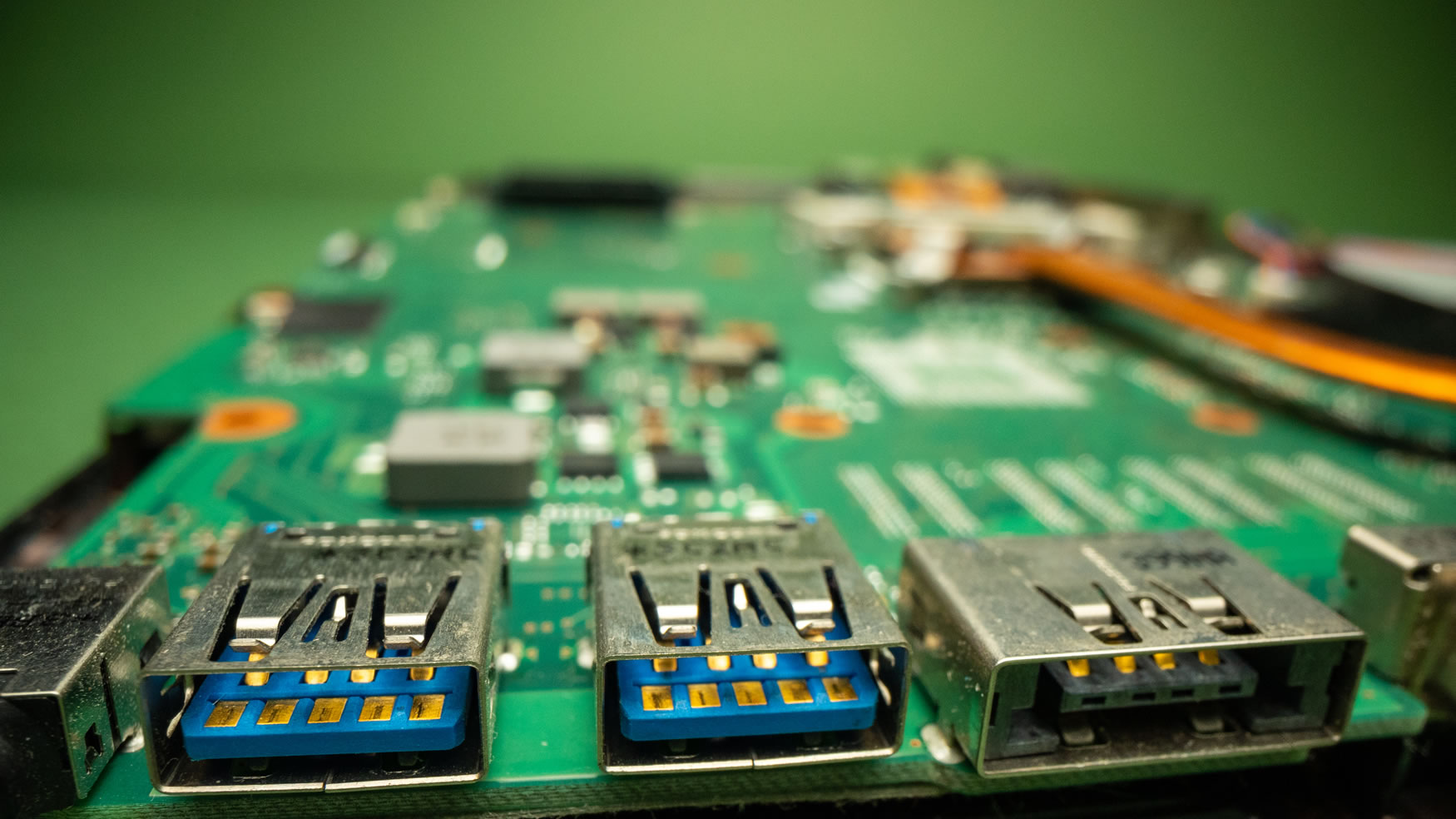

CUSTOM MOLDED CABLES AND CONNECTORS

We specialize in custom cable assembly and wire harness manufacturer with the abilities to manufacture custom cables at our facilities in Dongguan, China. We are one of the few custom cable manufacturers with the engineering expertise to manufacture a wide range of cables including custom cables.

PLASTIC INJECTION MOLDING

Perform DFM (Design For Manufacturability) analysis to ensure tooling friendly designs. With reference to the analysis report, related modifications can be made on the design accordingly for clients’ approvals prior to manufacturing.

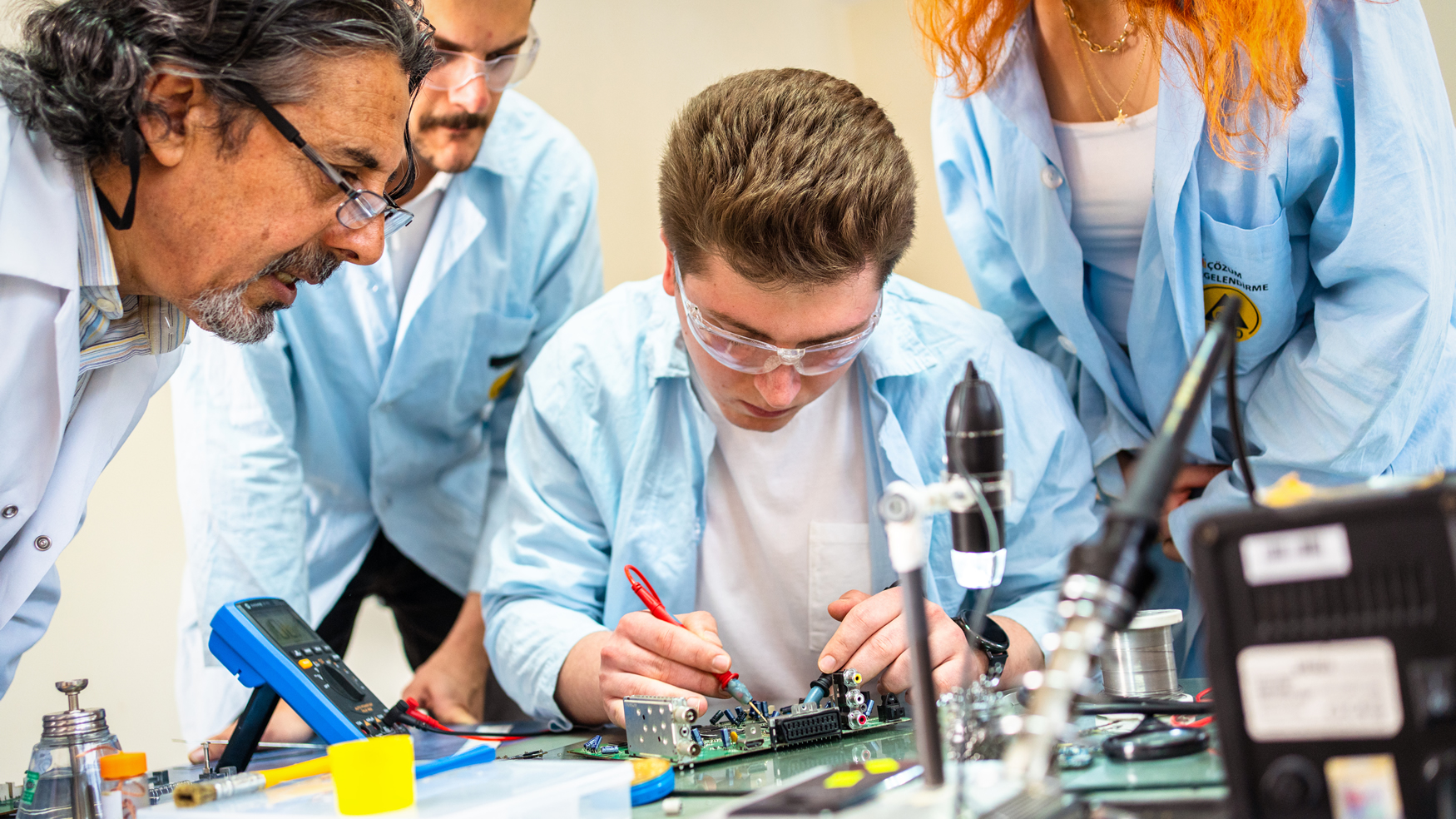

MECHANICAL ASSEMBLIES

In addition to our printed circuit board assembly capability, our system integration and product fulfillment have continued to grow in scope and volume. We take your product from design through prototyping and into manufacturing. We support your product throughout its life cycle.

MEMBRANE SWITCH OVERLAYS

We specialize in manufacturing custom membrane switch solutions with demanding reliability and stringent cosmetic requirements. We are proud to be industry leaders in producing membrane switches that meet or exceed our customers’ expectations.

PCB ASSEMBLIES

With Facilities in The USA, Taiwan, China and Mexico, we continue to strive to be a world-class Electronics Manufacturing Service (EMS) provider offering end-to-end solutions to our OEM customers in the areas of automotive, medical & healthcare, communication & networking, POS & banking as well as marine and aerospace electronics.

Transformers & Magnetic Assemblies

We offer complete in-house engineering and design services that will provide the most cost effective solutions for your magnetic requirements. Whether it’s a new design, customer design or existing product, we are able to deliver prototypes quickly while discussing any issues that need to be addressed with your engineers or design team.