Plastic Injection Molding

Perform DFM (Design For Manufacturability) analysis to ensure tooling-friendly designs. With reference to the analysis report, related modifications can be made to the design accordingly for clients’ approval before manufacturing.

Mold Capabilities:

Perform Mold Flow analysis to gain insights into the manufacturing process (filling, cooling, and warping) for achieving the most optimized mold design.

Our vast experience gives us the advantage of providing a customized design to meet every client’s specific needs. These facilities are well-versed in using hot runner systems and standard components from globally renowned brands like:

- Husky

- Mold-Masters

- MasterFlow

- DME

- Hasco

- Thermoplay

- We provide mold design generated in 3D with insert detailed drawings for every mold components

Mold Manufacturing Capabilities:

Molding Capabilities and Equipment:

Product finishing capabilities and equipment:

Product assembly capabilities:

To further reinforce customers’ confidence in our products and services, we undertake a comprehensive quality check prior to final packaging.

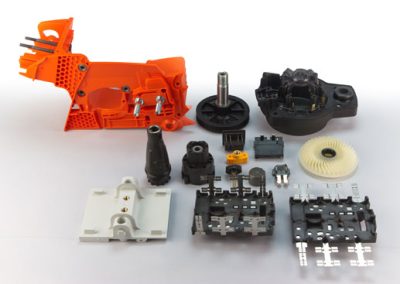

Below: are samples of injection-molded parts produced for important customers